Just How Industrial Scales Can Enhance Your Business Procedures

Just How Industrial Scales Can Enhance Your Business Procedures

Blog Article

Leading Features to Search For in High-Quality Industrial Scales

In the world of industrial operations, picking the right scale is critical for making sure efficiency and accuracy. Trick functions such as precision and accuracy, along with sturdiness and construct quality, play a substantial role in figuring out the suitability of a range for certain applications.

Precision and Accuracy

Making certain the accuracy and precision of industrial scales is critical for efficient operations across different industries. Precise measurements are vital in markets such as production, logistics, and food processing, where even minor inconsistencies can result in considerable monetary losses, compromised product quality, or regulatory non-compliance. High-quality industrial ranges are designed to deliver reliable efficiency, using innovative modern technology to ensure accurate weight readings.

The calibration procedure is crucial in keeping the accuracy of these scales. Regular calibration versus licensed recommendation weights guarantees that any drift in dimension is remedied, thus upholding conformity with market standards. In addition, using high-resolution load cells boosts the scale's capacity to find minute weight modifications, further enhancing its precision.

Toughness and Develop Quality

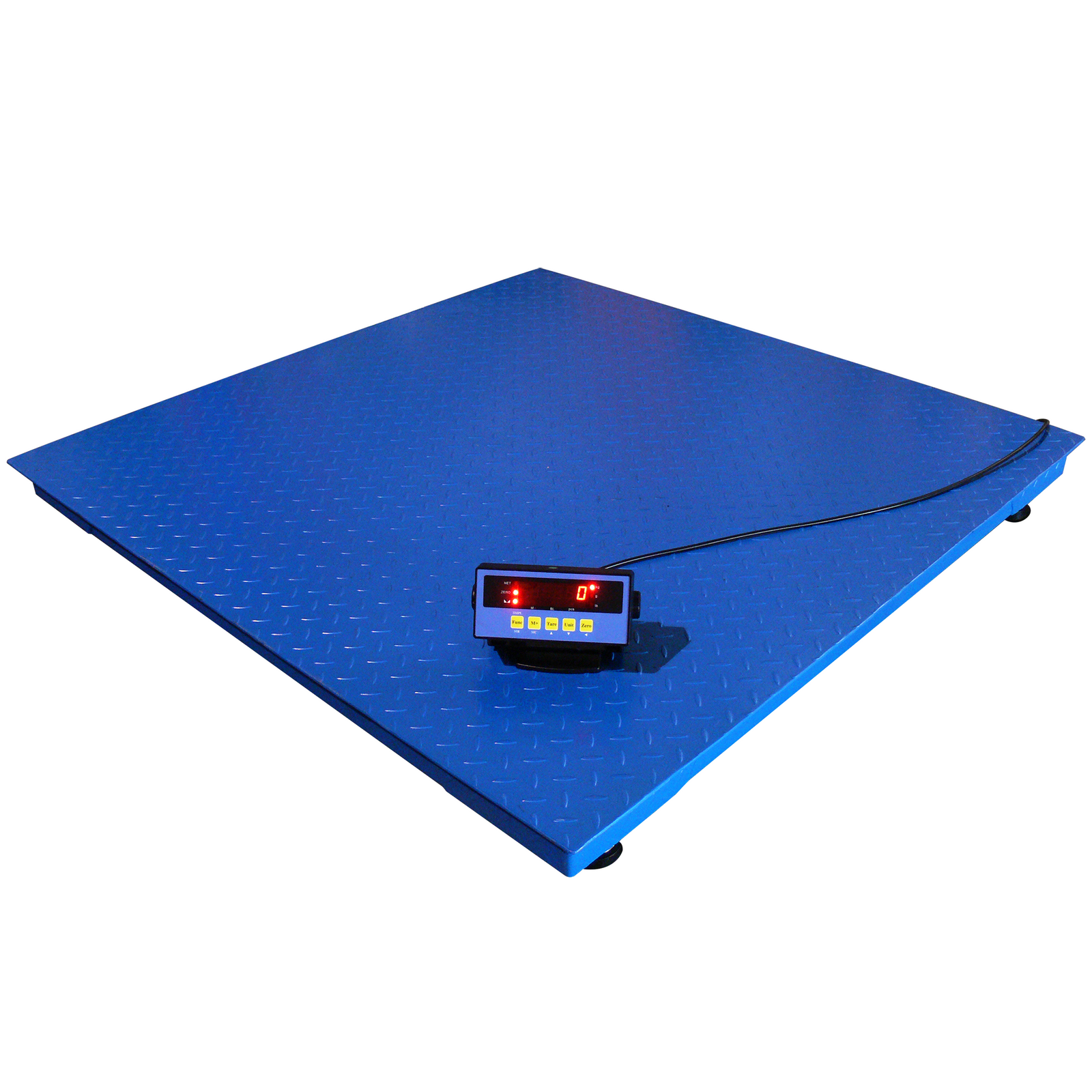

Durability and develop quality are important factors that figure out the longevity and integrity of industrial ranges sought after atmospheres. Industrial ranges are commonly subjected to rough problems, consisting of exposure to dirt, wetness, and hefty loads. The materials used in their construction play a crucial role in guaranteeing they can withstand these difficulties.

Top quality commercial ranges commonly feature robust housings made from materials such as stainless steel or aluminum, which not only supply structural honesty yet also withstand corrosion and wear. Furthermore, interest to detail in the design, such as strengthened edges and shock-absorbent feet, can enhance resilience and protect delicate elements from damage.

In addition, top-quality elements, consisting of lots cells and electronic components, contribute to the overall construct top quality. These parts ought to be designed to tolerate temperature variations and resonances generally located in industrial settings. Guaranteeing proper access security (IP score) is likewise crucial, as it shows the scale's capability to endure dirt and fluid exposure.

Eventually, picking commercial scales with premium durability and develop quality will cause an extra trustworthy, resilient solution that satisfies the rigorous demands of various commercial applications.

Load Capacity and Variety

When picking industrial scales, comprehending their lots capability and array is important for conference particular functional needs. Lots capability refers to the optimum weight that a range can properly gauge, while the variety suggests the range of weights the range can handle efficiently. It is critical to choose a range that not only satisfies current demands however likewise suits potential future needs.

Different industries have special weight measurement demands. As an example, a production facility might require ranges qualified of weighing heavy machinery components, while a lab could just require scales for lighter materials. Picking a range with an appropriate tons capability makes certain accuracy and accuracy, stopping overwhelming that can lead to equipment damages or incorrect analyses.

A scale that can gauge both light and hefty weights precisely can enhance operational efficiency, permitting for versatile applications. Spending in scales with appropriate lots capacity and variety substantially contributes to productivity, compliance with market requirements, and general operational dependability.

Ease of Use and Upkeep

In enhancement to user-friendliness, convenience of maintenance is another essential aspect to consider. try here Ranges that are made with obtainable components assist in routine maintenance jobs such as calibration, battery, and cleansing substitute. A modular layout can better simplify these processes, enabling quick repair work and very little downtime.

In addition, the products made use of in the building additional info of commercial scales play a significant duty in upkeep. Scales made from long lasting, corrosion-resistant materials are easier to tidy and much less susceptible to damages, which extends their lifespan and minimizes general operational expenses.

Routine upkeep schedules, guided by the producer's referrals, are necessary for making certain optimum performance. By focusing on convenience of use and upkeep, companies can make certain that their industrial ranges remain reliable, trusted, and efficient devices in their procedures. This brings about improved productivity and an extra reliable operations.

Connectivity and Integration Alternatives

Integrating commercial ranges right into existing operational structures is considerably boosted by robust connection alternatives. High-grade commercial ranges ought to offer multiple connectivity methods, including USB, Ethernet, and cordless alternatives such as Wi-Fi or Bluetooth. These attributes assist in seamless data transfer to central databases, ERP systems, or cloud systems, making it possible for real-time monitoring and coverage.

Moreover, advanced integration options permit compatibility with existing equipment, such as printers or barcode scanners, boosting and simplifying processes operations effectiveness. Scales that sustain industry-standard protocols, such as Modbus or RS-232, can quickly connect with various tools and systems, making certain a natural operational atmosphere.

An additional necessary aspect is the ability to incorporate with software services that assess and visualize data - Industrial Scales. Scales equipped with APIs or software application growth sets (SDKs) offer services the adaptability to personalize performances customized to their specific demands

Lastly, considering future scalability is crucial; picking ranges that can adapt to evolving technical improvements makes certain long-lasting worth and lessens the need for pricey replacements. In recap, evaluating connectivity and assimilation alternatives is essential when picking premium industrial scales that will improve operational performance and information administration.

Verdict

In verdict, picking high-quality industrial ranges demands careful factor to consider of a number of vital functions. Industrial Scales. Focusing on these features inevitably leads to boosted efficiency and long-lasting value in commercial applications, strengthening my blog the importance of informed decision-making in range choice.

In the realm of industrial procedures, choosing the right scale is crucial for guaranteeing effectiveness and accuracy.Ensuring the precision and precision of commercial scales is vital for efficient procedures throughout numerous industries. Tons capacity refers to the maximum weight that a scale can precisely measure, while the variety shows the range of weights the scale can manage properly. A manufacturing facility may require ranges capable of considering heavy equipment components, while a laboratory could only need ranges for lighter products. By focusing on ease of usage and upkeep, companies can make certain that their commercial scales remain reliable, trustworthy, and effective tools in their operations.

Report this page